Injection Molding Troubleshooting Tips.

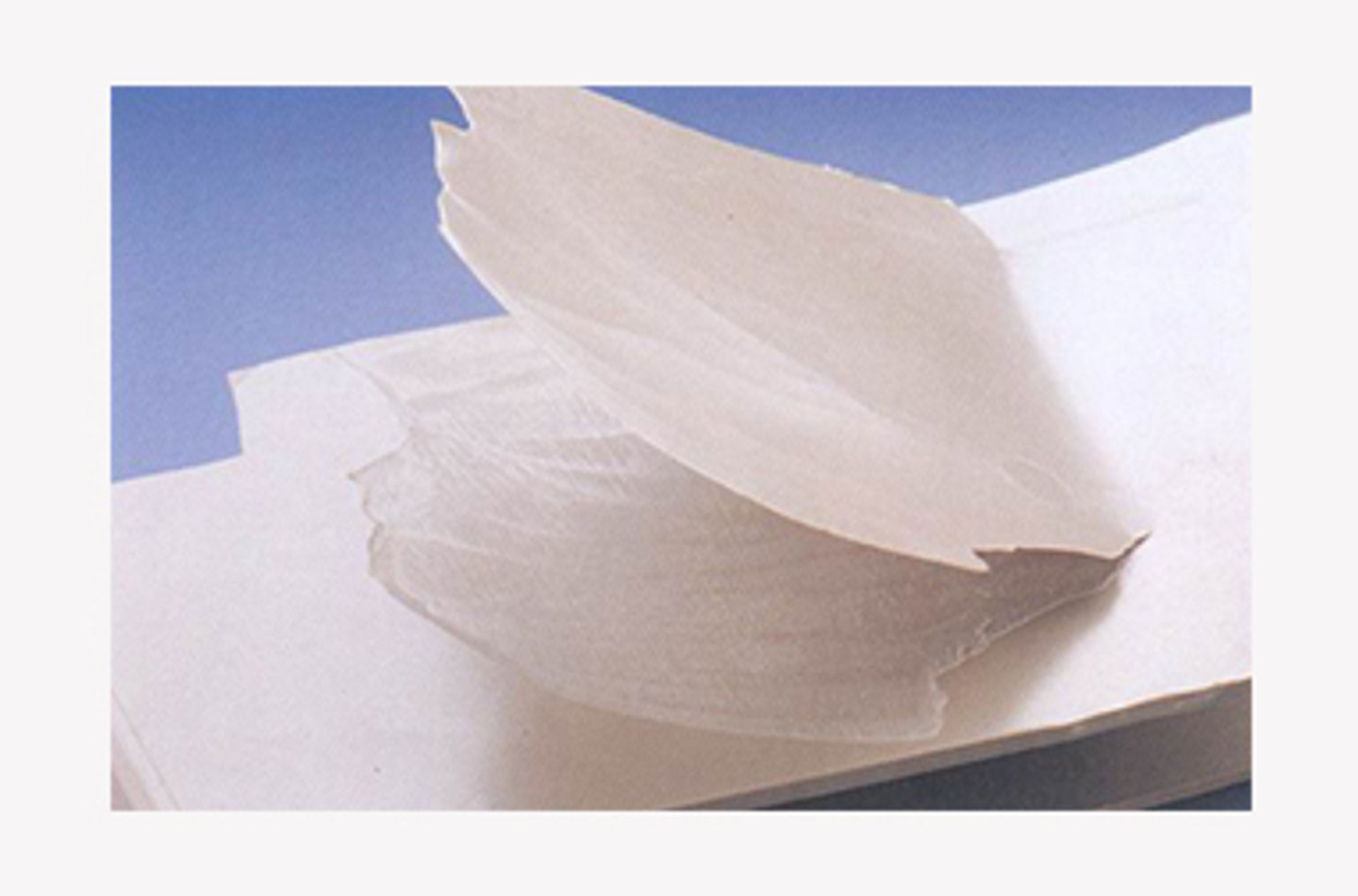

Tip #8: Delamination

Delamination, which may also be called lamination or layering, is a defect where the surface layers of a molded part can be peeled off. Delamination often occurs in the gate area, but can occur in any area of the molded part and can be a small or large defect. While this is most often caused by contamination or high shear, there can be other causes as well.

From a material standpoint, ensure that the material is properly dried. In the case of nylon, make sure that the material is not dried to too low moisture content as this can result in higher shear stress on the material during molding. Switching to an easier flowing grade of material, if allowed, will often help resolve the delamination problem. Ensure that the material is not contaminated with a foreign, incompatible polymer. Contamination is typically the #1 cause of delamination. If using regrind, ensure that the regrind is free from contamination and is properly dried. If necessary, consider reducing the amount of regrind being used.

From a processing standpoint it may be necessary to increase the mold temperature, melt temperature and/or reduce the injection speed. All of these changes can help to reduce the shear stress on the material which can prevent delamination from occurring.

From an equipment and tooling standpoint it may be necessary to increase the gate size in order to reduce the shear stress on the material. Too small of a gate, along with too fast of an injection speed, are the next most common causes of delamination. Some materials like ASA are more sensitive to shear stress and typically require larger gates and slow injection speed in order to not experience delamination.

If your parts are experiencing delamination the simplest thing might be to first modify the processing parameters (mold/melt temperature, injection speed) to reduce the shear stress on the material. If this doesn’t eliminate the problem, the next step would be too analyze the material for the possibility of contamination. If there is no foreign contamination then modification to the gate may be necessary.

Entec Polymers Technical Service Team