BASF Corporation

Product Finder

BASF, creating chemistry for a sustainable future. They combine economic success with environmental protection and social responsibility. The approximately 122,000 employees in the BASF Group work on contributing to the success of their customers in nearly all sectors and almost every country in the world. Their portfolio is organized into six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions.

BASF Commitment to Sustainability

Striving to create endless possibilities for you through our portfolio of sustainable engineering plastics and polyurethanes, we have set ourselves ambitious sustainability goals. These goals help our industry get closer to a net-zero future and a true circular economy.

- Reduce 25% of CO2 emissions by 2030

- Contribute significantly to BASF Group's €17 billion circular sales by 2030

- Achieve net zero CO2 emissions by 2050

Performance plastics align with the circular economy

Circular economy is a principle already in practice at BASF. It includes using resources wisely and designing products with the minimum amount of waste and impact on the environment. The goal is to move away from a linear model of “take, make, dispose” toward a regenerative, circular model where resources are reused and recycled and waste is reduced. No one organization can create the circular economy. It requires all of us in the plastic value chain to align. By giving plastics a new life, you and BASF can create unique opportunities that enable a circular future.

Solutions for eMobility Applications

The key to crafting viable eMobility applications lies in material performance. Many eMobility solutions can only be implemented successfully by using highly versatile engineering plastics, polyurethane systems and specialty elastomers.

- Battery Components

- Charging Infrastructure

- Connectors, Cables & Cable Management

- Thermal Management

- Electric Motor

- Electric Powertrain

Battery Components

Highly efficient battery systems are key to the success of electromobility. Individual components need to meet high-performance standards during normal driving and in the event of damage or accidents, which means that any material used needs to be carefully assessed by its flame retardancy, electric isolation, thermal conductivity and cooling compatibility. With Ultramid®, Ultramid® Advanced and Ultradur® family of products we can help to make your ambitions for high performance battery components reality.

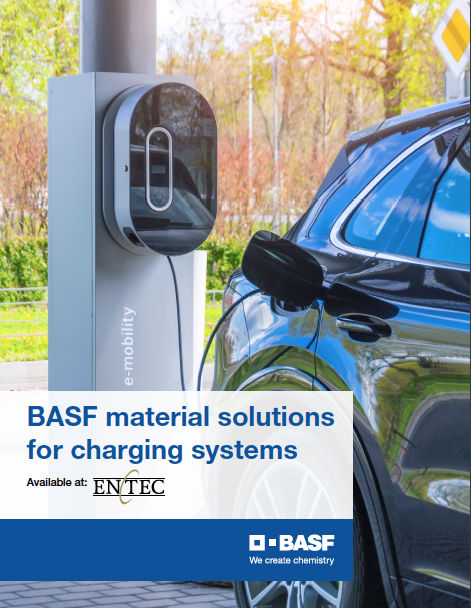

Charging Infrastructure

Charging infrastructure components for eMobility must exhibit excellent mechanical performance at elevated temperatures and high dimensional stability, to endure demanding conditions while offering safety and long-lasting durability for color, surface finish, and UV stability. With Ultramid®, Ultramid® Advanced and Ultradur® family of products your charging infrastructure components will stand the test of time and meet the most ambitious requirements.

Connectors, Cables & Cable Management

Where electricity flows, plastics have to show excellent electrical isolation, outstanding flame retardancy and hydrolysis resistance while meeting the relevant IEC standard. For sealed connectors the compatibility to LSR is of high importance. Are you looking for extrudable products or colorability in durable orange? All to be found within our product range consisting of Ultramid®, Ultramid® Advanced and Ultradur®.

Thermal Management

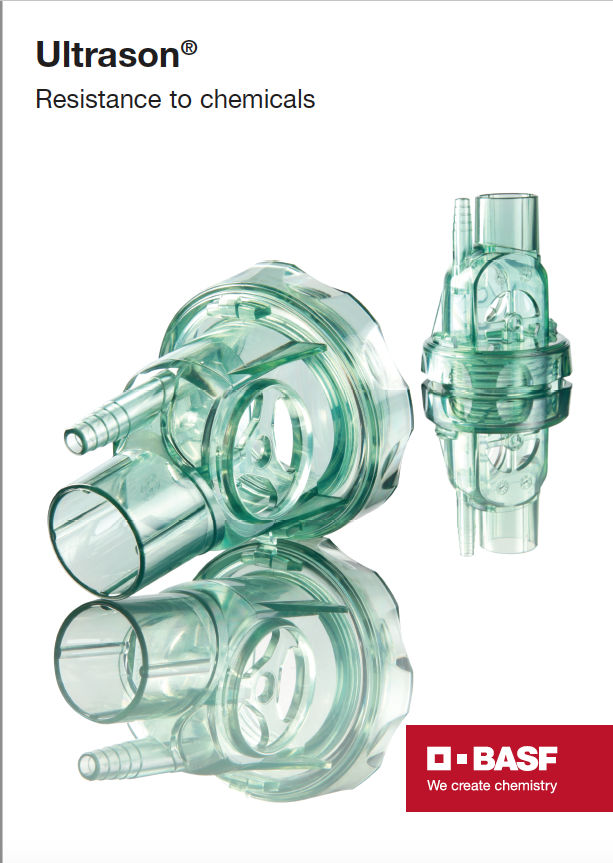

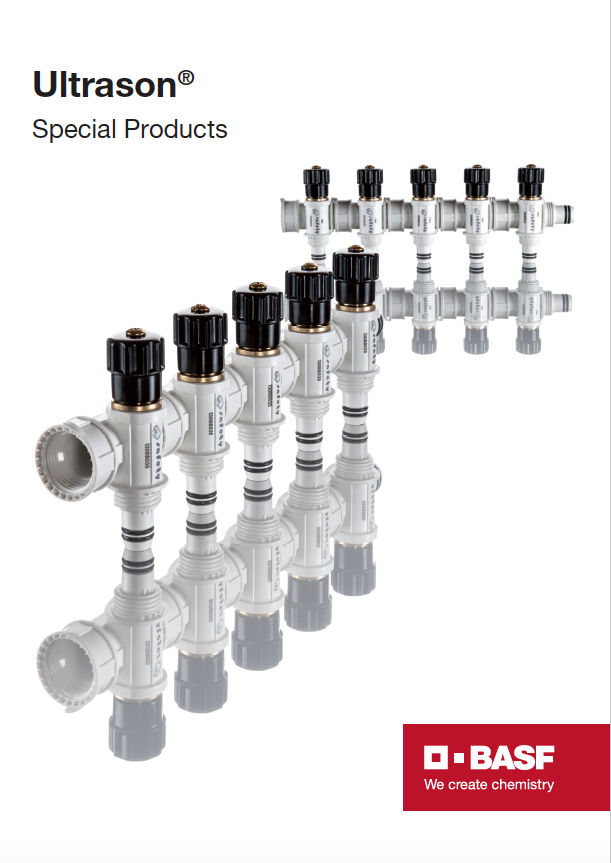

Thermal management is crucial for electric engines. Components like water pumps, heaters, fittings as well as pipes benefit from the excellent media resistance, the leak tightness and compatibility with many coolants of BASFs’ polyamide Ultramid® and the products in the polyphthalamide portfolio of Ultramid® Advanced. With these high-performance materials, laser welding is also possible.

Electric Motor

The electric motor is the heart of any e-vehicle. Motor housing and motor mounts as well as intricate components like stator/rotor, rotor end caps, bus ring and connector supports can work reliably thanks to BASF’s engineering plastics Ultramid® Advanced (PPA), Ultrason® (PESU) and the long-glass fiber reinforced Ultramid® Structure. They are characterized by high temperature and media resistance, excellent strength and electric compatibility – and all are available as flame retardant grades.

Electric Powertrain

From high voltage housing for power electronics, to fuse boxes, connectors and inlets, flame retardancy, electric isolation, heat aging and orange colorability are key criteria for any material consideration. Whether you are looking for solutions for fuel cell, battery powered or hybrid vehicles, BASF's Ultramid®, Ultramid® Advanced, and Ultradur® familiy of products will move your electric powertrains forward. All are available as flame retardant grades, among them non-halogenated flame-retardants. BASF Monomers.