Medium Density Polyethylene (MDPE) is produced in a low pressure rector and is defined as having a density between 0.930 and 0.940 g/cm3. MDPE offers a good balance of strength, stiffness, and toughness and is most often used for rotational molding. MDPE grades for rotational molding contain additional antioxidants and UV stabilizers in their formulation. Common rotational molded applications include playground equipment, storage tanks, large bins, portable barriers, carts, toys, kayaks and sporting goods.

Polymer Characteristics

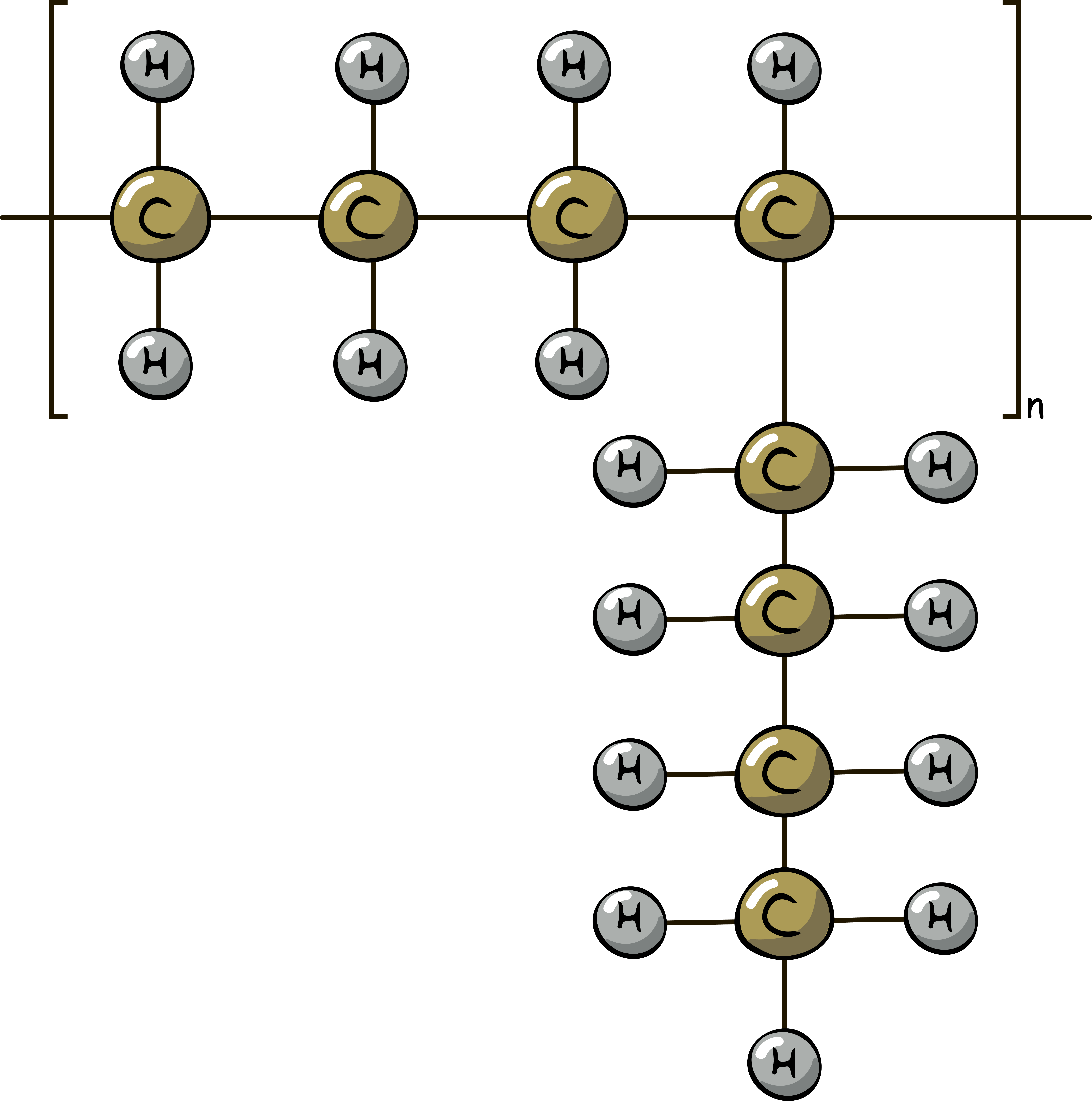

Medium Density Polyethylene (MDPE) is a type of polyethylene with a molecular structure that falls between Low Density Polyethylene (LDPE) and High Density Polyethylene (HDPE). This unique structure gives MDPE distinct characteristics, making it suitable for a variety of applications. The molecular arrangement of MDPE is less branched compared to LDPE, imparting it with higher tensile strength, greater stiffness, and improved resistance to stress cracking. However, MDPE maintains a higher level of flexibility compared to HDPE, making it the perfect choice for different industries.

MDPE is known for its excellent chemical resistance, ensuring durability and reliability in applications where exposure to various chemicals is a concern. Additionally, MDPE exhibits good impact resistance and environmental stress crack resistance, making it suitable for outdoor applications. The combination of these characteristics positions MDPE as a preferred material for applications such as drums, totes, containers and kayaks.

Processing Methods

MDPE can be processed using various methods, providing flexibility to manufacturers in producing a wide range of products. Common processing methods for MDPE include:

- Injection Molding: Ideal for manufacturing intricate and detailed components, such as fittings, valves, and small containers.

- Blow Molding: Used in the production of bottles, containers, and tanks, this method leverages MDPE's flexibility and impact resistance.

- Extrusion: This versatile method is employed for producing pipes, tubing, films, and sheets. MDPE's processability in extrusion allows for the creation of different shapes and sizes.

- Rotational Molding: Suited for large, hollow items like tanks, containers, and playground equipment, leveraging MDPE's impact resistance.

- Compression Molding: Applied in the production of medium to large-sized parts, offering flexibility in design and application.

The choice of processing method depends on factors such as the intended application, required mechanical properties, and the complexity of the final product. MDPE's ease of processing contributes to its wide use in diverse industries.

Typical Applications

The distinctive properties of MDPE make it well-suited for a variety of applications. Its balance of strength and flexibility makes it a preferred choice for the production of pipes used in gas and water distribution. MDPE's resistance to cracking and stress corrosion, combined with its moderate density, makes it an ideal material for outdoor applications where exposure to environmental elements is a concern. Additionally, MDPE is employed in the manufacturing of films, sheets, and packaging materials, showcasing its versatility across different industries.

Density and Mechanical Properties

The density of MDPE is higher than LDPE but lower than HDPE. This moderate density imparts MDPE with a balance of mechanical properties, making it more rigid than LDPE while retaining a degree of flexibility. MDPE's mechanical characteristics make it suitable for applications requiring both strength and ductility such as in the production of pipes, tubing, containers and rotational molded products.

Thermal Properties

MDPE exhibits favorable thermal properties, including a melting point lower than HDPE which can be an advantage in some applications.