BioBlend®

Product Finder

Learn more about our new customer portal

Customer Portal

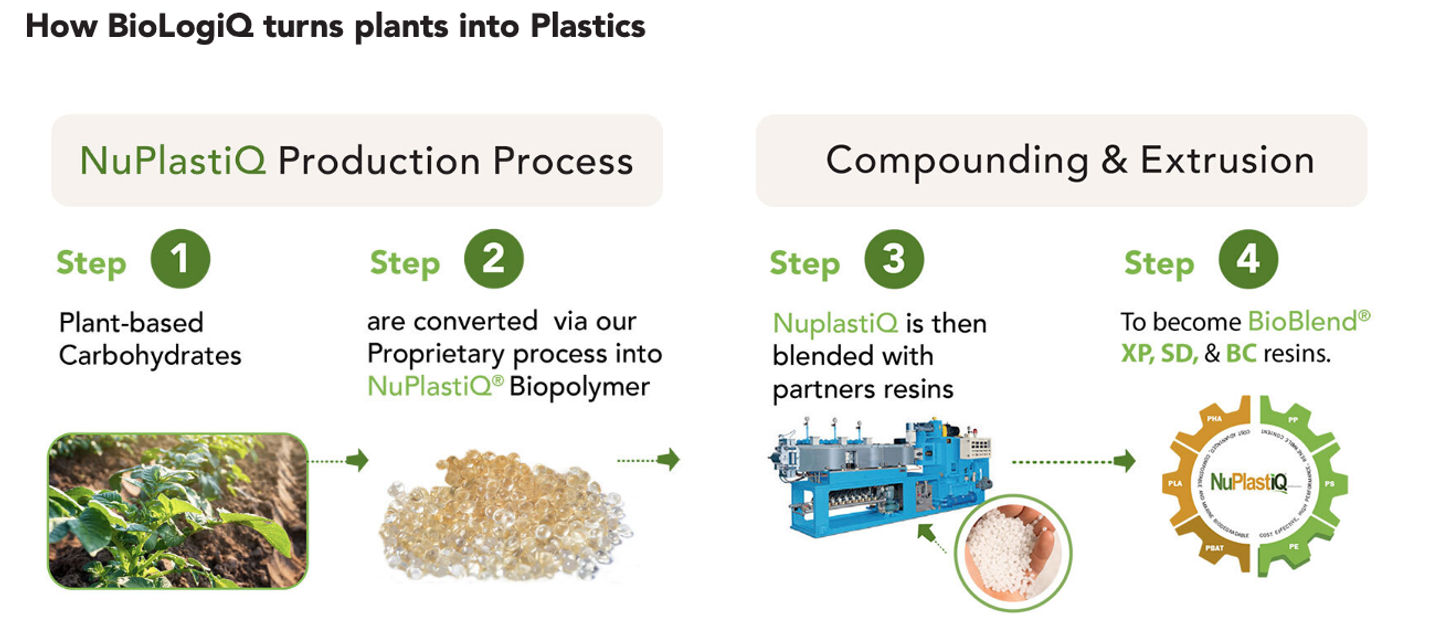

BioLogiQ has invented a process for making homogeneous blends of NuPlastiQ BioPolymers (having low crystallinity) with other polyolefins (having high crystallinity). The resulting thermoplastic blend is called a BioBlend.

Since iQ-based products have a higher modulus (strength) than many polyolefins, BioBlends can be used to make plastic items that are stronger than those made with pure polyolefins. The chemical and mechanical bonds of plastic products made with BioBlends exhibit beneficial properties from each of the base resin feedstocks.

NuPlastiQ Family of BioBlends®

Compounding NuPlastiQ BioPolymer with legacy plastics produces BioBlend XP, XD, and BC Resins. These will meet or exceed the performance of products made from traditional plastic.

High-Performance: BioBlend XP High-Performance Resins for packaging will maintain or even increase the overall strength of plastics such as polyethylene, polypropylene, or polystyrene. They can also reduce material use, energy consumption, fossil fuel-based plastics usage, and greenhouse gas (GHG) generation by up to 50%.

Durable: BioBlend XD High Durability Resins for durable goods and rigid containers provide improved sustainability metrics related to reduced fossil fuel-based plastics usage and lower greenhouse gas generation while maintaining durability and other strength characteristics.

Compostable and Biodegradable: BioBlend BC Biodegradable and Compostable Resins for packaging and films are produced by mixing our NuPlastiQ CG (Certified Grade) resin with similar plastics such as PBAT, PLA, and PHA. BioBlends are designed to retain or enhance compostability in industrial facilities and to do so price competitively. BioBlend BC enables:

Using NuPlastiQ instead of starch powder to make BioBlends makes it possible for any plastics product manufacturer to make high-quality, more sustainable, plastic products that have not been possible using starch in the past. Companies that tried to use starch or TPS in the past and were not successful can now easily use NuPlastiQ BioBlend resins on their existing equipment to make high-quality and high-performance products.

Using BioLogiQ’s process on standard compounding machines, BioBlends can be made for your application without the need for special equipment such as side feeding ports for starch powder injection.

BioBlends have been successfully made and are in use with many traditional fossil- fuel resins such as LDPE, LLDPE, HDPE, PS, PP, and PBAT, as well as with bio-based resins such as PHA, PLA, and PBS, etc. BioLogiQ continues to develop blends with various grades of the many plastic resins available in the marketplace.

BioBlends are made by blending BioLogiQ’s NuPlastiQ resin with other conventional resins. BioBlends normally start as Masterbatch pellets containing 50% iQ (NuPlastiQ) and 50% fossil-fuel resin which are blended on standard compounding equipment. Masterbatch BioBlends are then blended further at the final process to obtain the desired NuPlastiQ content.

Example: for typical film applications, the BioBlend Masterbatch that contains 50% NuPlastiQ and 50% virgin LLDPE resin would be fed into the blown film hopper along with an additional 50% LLDPE base resin so that the final BioBlend content in the finished film would be 25% NuPlastiQ and 75% LLDPE. Other ratios are also possible and can be easily established by the appropriate down blending configuration.

BioLogiQ can provide BioBlend compounded resins directly from our factoryies in Idaho/USA and Shaoguan/China for trial and production activities. Please contact the factory for a direct discussion of your specific needs.