Styroflex®

Product Finder

Learn more about our new customer portal

Customer Portal

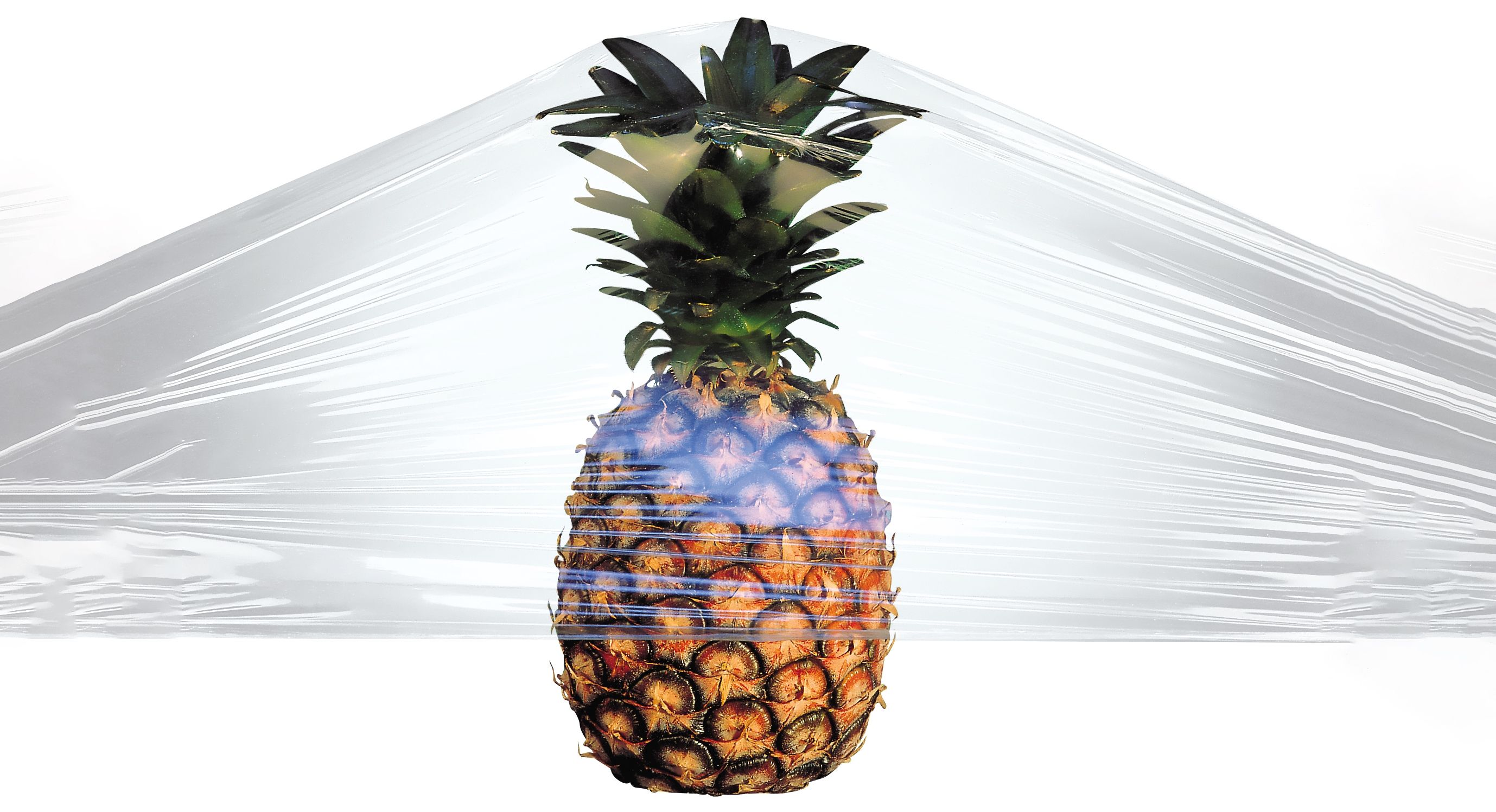

Styroflex® is a styrene-butadiene block copolymer (SBC) with the properties of a thermoplastic elastomer (S-TPE), suitable for extrusion (including both blown and cast film) and injection molding. Characterized by a combination of high resilience and toughness, optical clarity and process stability Styroflex® offers as well a good printability and good adhesion to many different polymers. In film applications, Styroflex® provides excellent stretch recovery, superior transparency and puncture resistance, high oxygen and moisture permeability. It is also employed as a high performance additive to increase toughness and e.g. the stress cracking resistance of styrenic and olefinic polymers.

Key Applications:

Key Properties:

Styroflex® ECO is a styrene-butadiene block copolymer (SBC) with the properties of a thermoplastic elastomer (S-TPE), suitable for extrusion (including both blown and cast film) and injection moulding. Characterised by a combination of high resilience and toughness, optical clarity and process stability, Styroflex ECO offers as well a good printability and good adhesion to many different polymers. In film applications, Styroflex ECO provides excellent stretch recovery, superior transparency and puncture resistance, high oxygen and moisture permeability. It is also employed as a high performance additive to increase toughness and e.g. stress cracking resistance of styrenic and olefinic polymers.

Styroflex ECO resins are a compliant product leading to a substitution of fossil source styrene with RSB-certified bio-attributed styrene. Over its production lifecycle, Styroflex ECO resins provide greenhouse gas savings compared to a fossil fuel equivalent. RSB Participant code: 2114