XYRON™

Product Finder

Learn more about our new customer portal

Customer Portal

Xyron™ engineered resins are composed of alloys of polyphenylene ether (mPPE) with polyphenylene sulfide (PPS), polypropylene (PP), polyamide (PA), polystyrene (PS) or other polymeric materials.

Under the Xyron™ brand, we produce unique alloy compounds of Polyamide (PA), Polystyrene (PS) and polyphenylene ether (PPE) that deliver diverse performance attributes. These include suitability for painting, low warpage, high-temperature performance and flame resistance. This combination makes these compounds ideal for use in critical automotive and electronic components.

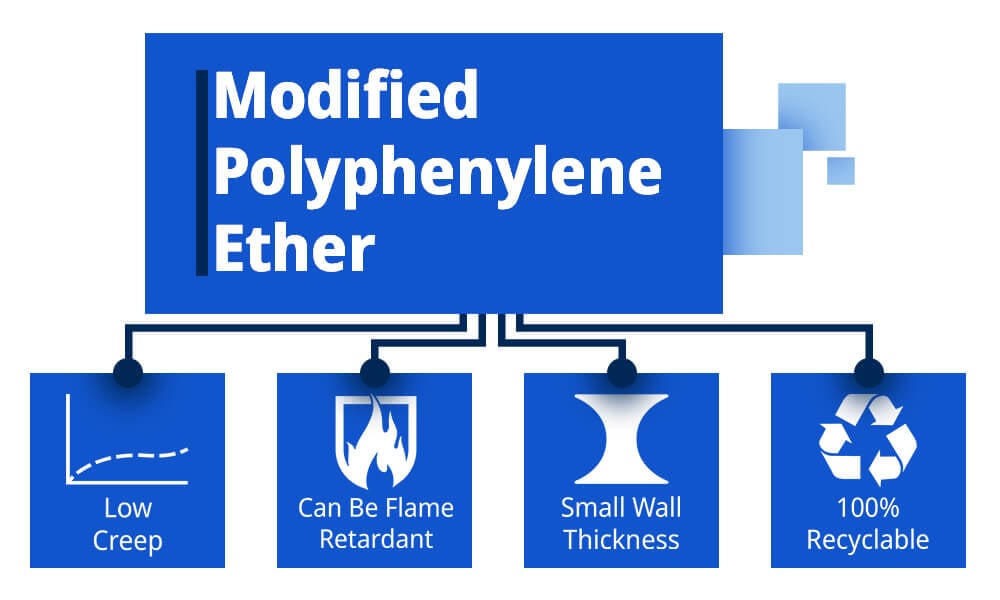

Xyron™ is an alloy compound of modified polyphenylene ether, or mPPE. As a thermoplastic material first created for use in the automotive industry, mPPE is incredibly tough, with good temperature resistance and moderate mechanical properties. It has excellent dimensional stability, low creep and can be effective flame retardant.

Modified polyphenylene ether enables smaller wall thickness design, excellent dielectric properties, and potentially lowers overall weight. Xyron™ can be found in the medical, robotics, appliance and automotive industries.

Linear and non-crystalline, thermoplastic polyphenylene oxide (PPO), also called Polyphenylene ether (PPE), is considered one of the most important engineering plastics due to its exceptional chemical resistance, strength and resistance to heat distortion at high temperatures.

Notable attributes of our mPPE polymer engineering resins include:

Modified polyphenylene ether resin combines moldability and chemical resistance of crystalline resin with high-temperature rigidity and dimensional stability of amorphous resin. As a result, the compound can be used to create stable products in multiple environments.

Common uses include components in copiers and printers, electrical devices like circuit breakers and connectors, water softeners and vending machines.

Modified polyphenylene ether suits a range of applications, including use in: