Rynite®

Product Finder

Learn more about our new customer portal

Customer Portal

Rynite® Thermoplastic Polyester (PET) resins with distinctive crystallization characteristics provide outstanding physical properties and superior thermal and chemical resistance with the ability to support higher temperature exposure.

What is PET?

Semicrystalline injection molded PET, commonly known as Polyethylene Terephthalate, is a polymer that offers the right solution for a variety of special applications. For general Polyethylene Terephthalate injection-molding applications, well-crystallized parts are preferred to minimize post-molding shrinkage and deformation.

This objective is achieved by the use of appropriate nucleating and plasticizing agents, leading to fast cycling, typically glass-reinforced and/or mineral-filled materials. PET compounds of this type offer high strength, good impact resistance, high-temperature tolerance and the ability to withstand a broad range of chemicals.

Chemical Name: Polyethylene Terephthalate

Delivery Form: Pellets

Polyethylene Terephthalate Uses:

Why Rynite® PET?

With its lightweight, glass-reinforced composition, dimensional stability, durability and high-gloss finish, Rynite® PET is preferred across a wide range of applications, particularly as a replacement of die-cast metals and thermosets. It offers superior flow characteristics as well, which means it fills complex, thin-walled molds with less injection pressure than is needed with other resins—a big advantage in the miniaturization of parts.

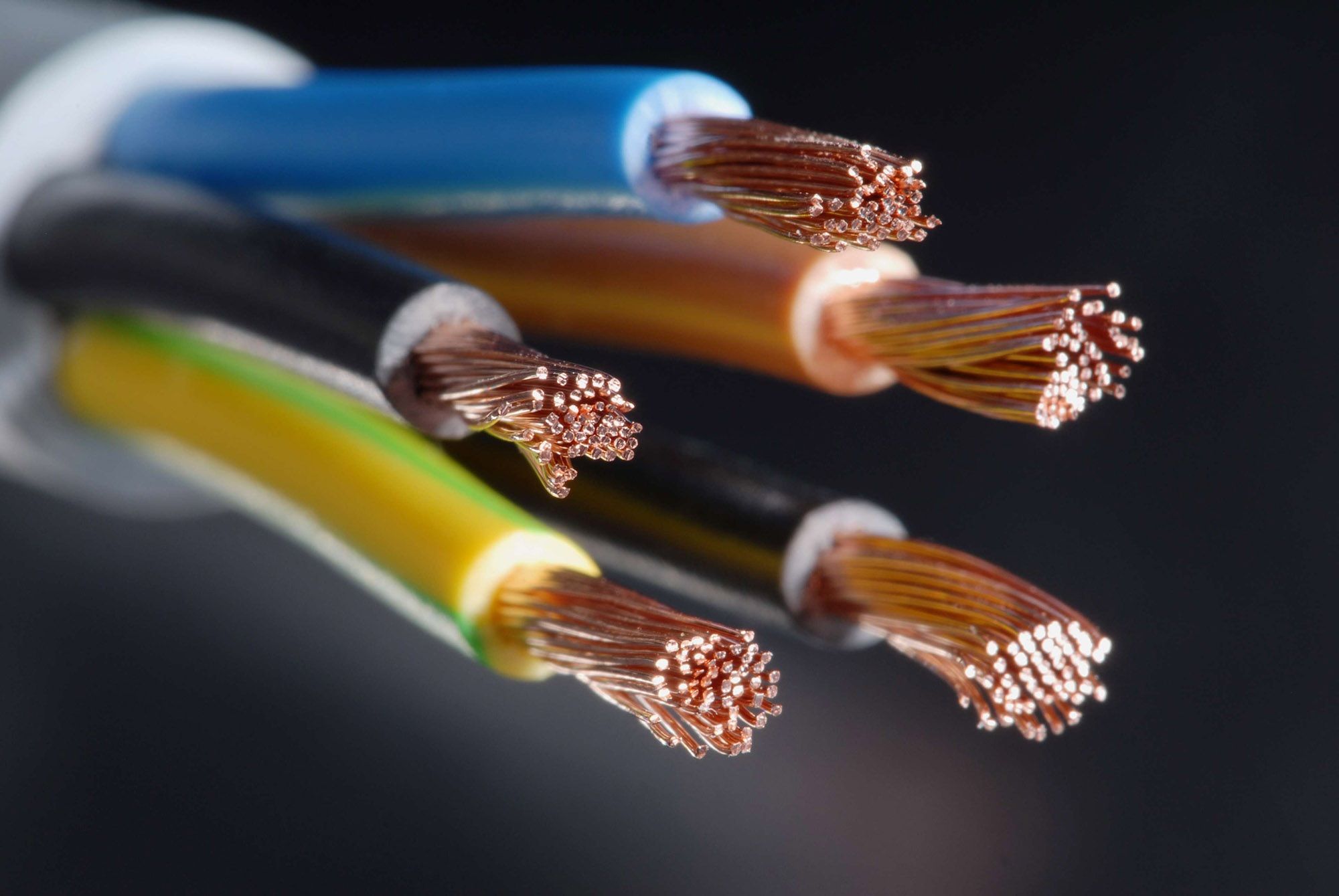

Rynite® Polyethylene Terephthalate (PET) helps make electrical devices, photovoltaic panels, switches and other critical energy components stronger and reliable. It’s one big reason why Celanese offers the industry’s largest portfolio of pre-approved Underwriters Laboratories (UL) Electrical Insulation Systems (EIS) and recognized to IEC standards products.

Technical Attributes:

PET Polymer Processing:

Industries

Polyethylene Terephthalate Applications